SMK Motorcycle Helmets

THE SMK STORY

SMK represents a new concept. One that’s built on 50 years of experience and expertise of the largest motorcycle helmet manufacturer in the world.

It starts with Studds, a highly respected, global company formed in 1972 to produce a singular product: motorcycle helmets, with a singular focus: the highest quality.

It was a humble beginning. The entire operation, including design, testing, manufacturing and packaging, took place in a garage. Innovation became a habit, if only to find space to get the job done.

But the focus never blurred. The company was unrelenting in delivering top quality at competitive price points.

By the 2000s, with the competition unable to beat the value that Studds offered, the company had become a market leader, known as the go-to choice for quality helmets and accessories.

THE SMK CONCEPT

Despite its success, the company wasn’t known as a premium manufacturer outside its traditional markets across Europe and Asia.

To change all that, the company launched SMK in 2015.

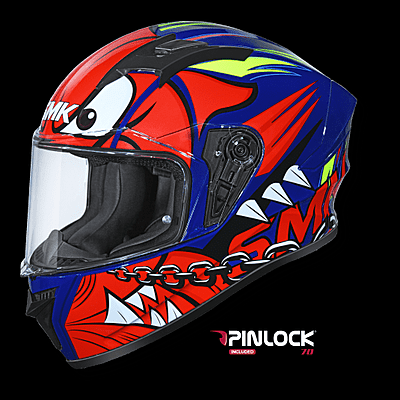

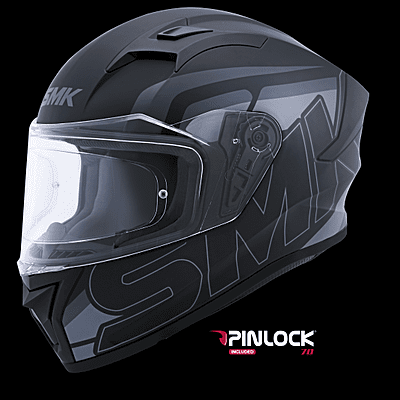

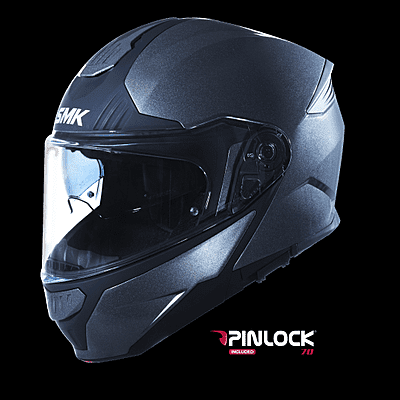

The new brand combined the inventive quality that made Studds famous, the aesthetics of Italian design, advanced technologies and innovative materials to offer a new benchmark for premium motorcycle helmets.

One that eclipses the competition not only in quality, but in safety, innovation, comfort and design. One that all riders can enjoy within their budget.

FULFILLING THE CONCEPT

With quality as the mantra in everything we do, the path to realizing the vision and values of SMK was clear. Offer what no other motorcycle helmet manufacturer could.

More than just testing and inspection protocols, quality assurance is infused in everything we do; and in doing everything in-house. From initial design concepts to final packaging and delivery, we are the only helmet manufacturer in the world to keep the complete cycle of production under our control.

The SMK helmet manufacturing facilities are the only ones in the industry with in-house laboratories that are certified to meet ECE (UN Regulation No. 22) and DOT (U.S. Department of Transportation) safety standards.

The technology in each of the four integrated SMK production facilities is constantly reviewed, analyzed and updated.

- In-house design studios

- Fully-automated EIRT injection moulding

- Fully-automated UV-resistant polyurethane paint processing

- In-house production of EPS (expanded polystyrene) – a key safety material

- Automated silicone hard coating for face shields

Exceptional standards of safety, quality and performance don’t come from everyday parts and materials. One example is SMK’s EIRT (Energy Impact Resistant Thermoplastic), a formulation designed for added impact protection and improved scratch resistance.